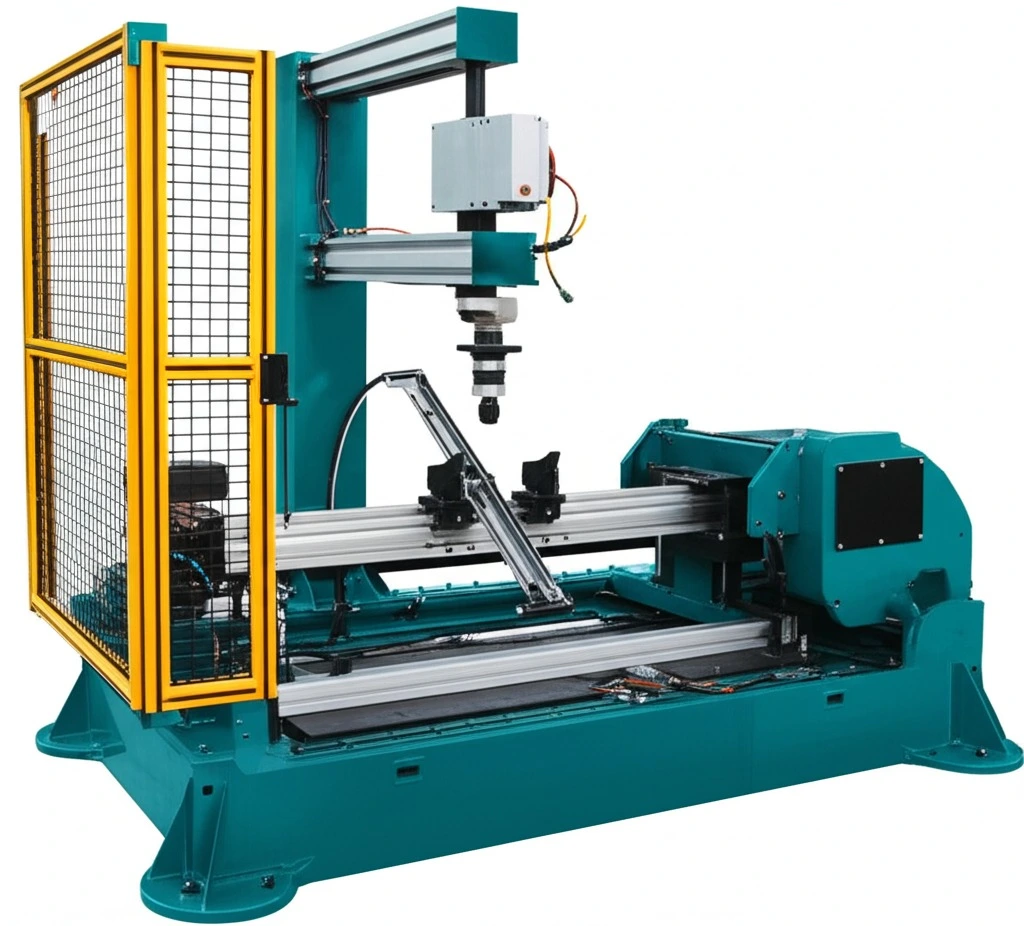

Window Regulator Riveting SPM

Fast Assembly. Strong Connections. Reliable Performance.

Motionworks Robotics’ Window Regulator Riveting SPM (Special Purpose Machine) delivers a high-speed, fully automated solution for the precise riveting of window regulator components. This system is designed for Tier-1 automotive suppliers and OEMs who require consistent quality and durability in their assembly processes.

Engineered with advanced pneumatic and servo-driven technology, this SPM ensures every rivet is perfectly set with the correct force and consistency. It seamlessly integrates into your production line, using integrated vision systems to verify component presence and alignment. The result is a highly reliable and efficient machine that significantly reduces manual labor, improves product quality, and increases overall production speed.

Key Features

Precision Riveting Technology

Our SPM uses a servo-controlled riveting head that provides consistent force and stroke, ensuring every rivet is formed perfectly. This eliminates loose connections and guarantees the long-term durability of the window regulator.

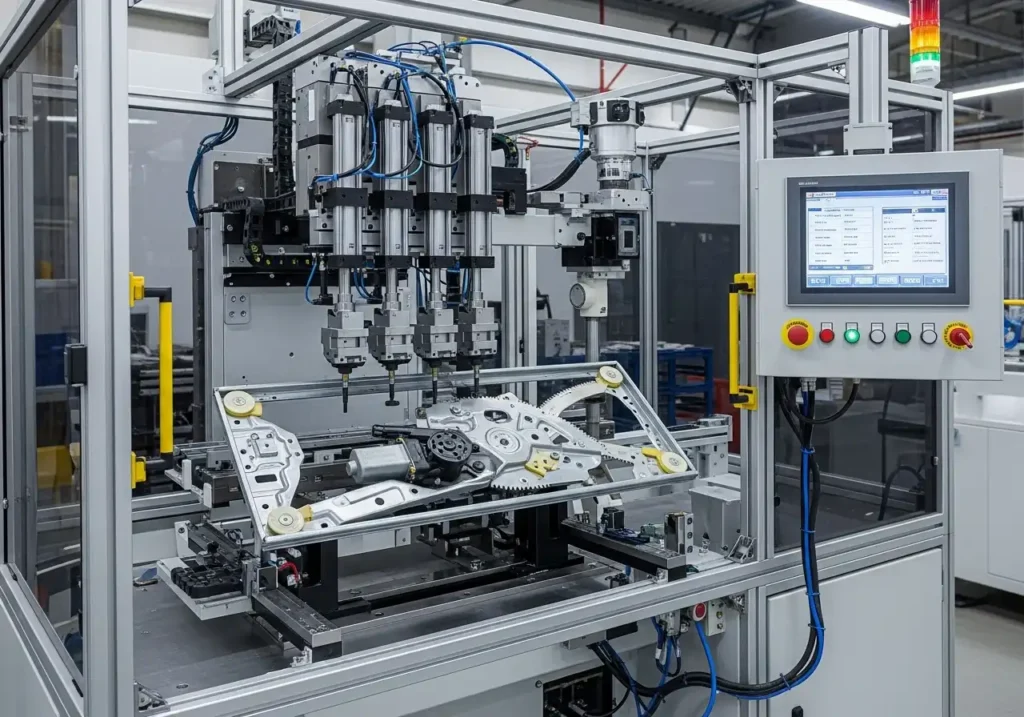

Integrated Vision Systems

AI-powered cameras and sensors verify the precise position of the window regulator components and the presence of all rivets before each operation. This proactive inspection prevents assembly errors and ensures the highest level of product quality.

Modular & Adaptable Design

The modular architecture allows for quick tooling changeovers and easy reconfiguration to accommodate different window regulator designs. The system can be quickly adapted to new parts with minimal disruption to your production schedule.

Satisfaction Rate

What the SPM Does

Our Window Regulator Riveting SPM is engineered to handle:

- Automatic Part Loading & Clamping

- Vision-Based Part Alignment & Verification

- High-Speed Rivet Feeding

- Servo-Controlled Riveting

- In-Process Quality Checks

- Automated Part Unloading

Performance Highlights

Exceptional Assembly Precision The combination of servo control and vision technology ensures that every rivet is installed with sub-millimeter accuracy, leading to a significant reduction in defects and rework.

High Throughput & Efficiency Designed for continuous, high-speed operation, the SPM maintains a smooth and consistent workflow, helping you meet demanding production targets without bottlenecks.

Minimal Downtime With robust components, self-diagnostic capabilities, and a user-friendly interface, the system is built for maximum uptime and easy maintenance, minimizing service interruptions.

- Have Questions? Ready to Automate?