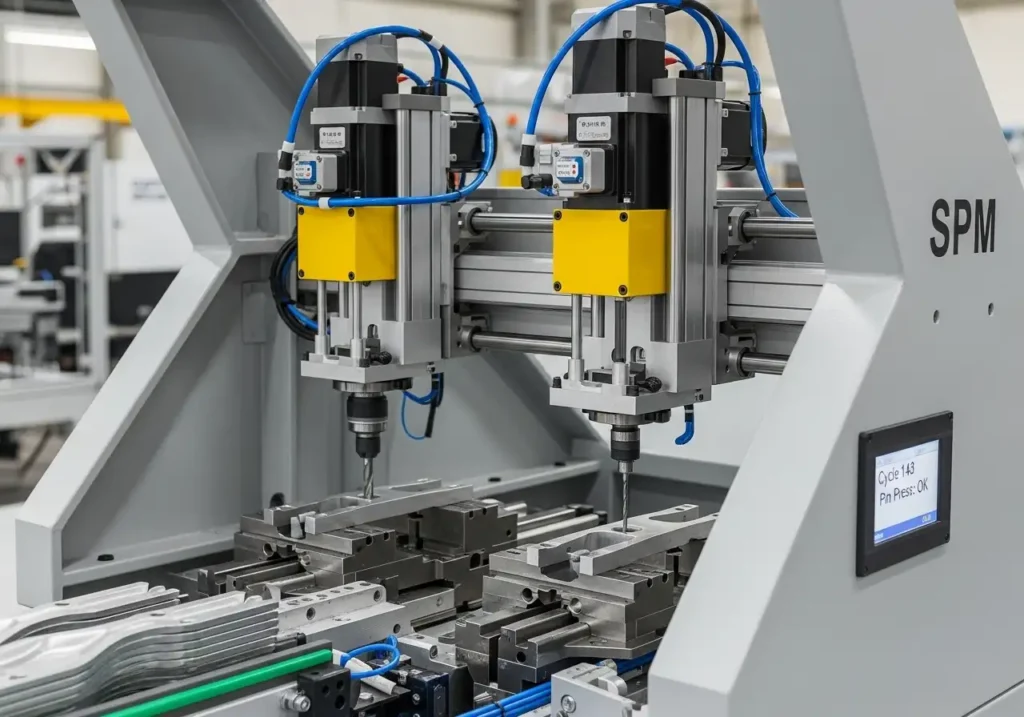

Fork Drilling & Servo Pin Pressing SPM

Integrated Precision. Flawless Assembly. Unmatched Efficiency.

Motionworks Robotics’ Fork Drilling & Servo Pin Pressing SPM (Special Purpose Machine) delivers a fully automated, two-in-one solution for high-precision drilling and pin pressing of fork components. This system is designed for Tier-1 automotive manufacturers and other industrial clients who demand superior quality and repeatable accuracy in their assembly processes.

Engineered with advanced servo-driven axes and a robust drilling unit, this SPM ensures that every hole is drilled to the exact specifications and every pin is pressed with the correct force and depth. It integrates seamlessly into your production line, using intelligent vision systems for precise part alignment and verification. The result is a highly reliable and efficient machine that boosts output while eliminating assembly errors and material waste.

Key Features

Dual-Action Functionality

This single machine combines high-speed, accurate drilling with servo-controlled pin pressing, streamlining your production line and reducing the need for multiple pieces of equipment.

Servo-Controlled Precision

Achieve impeccable accuracy in every operation. Servo motors provide precise control over drilling depth, feed rate, and pin pressing force, ensuring consistent quality and performance for every fork assembly.

Integrated Vision Systems

AI-powered cameras and sensors verify the precise position of the fork component before any operation begins. This ensures perfect alignment for both drilling and pressing, guaranteeing a flawless final product and minimizing scrap.

Satisfaction Rate

What the SPM Does

Our Fork Drilling & Servo Pin Pressing SPM is engineered to handle:

- Automatic Part Loading & Clamping

- Vision-Based Part Alignment

- Precision Fork Drilling

- Servo-Controlled Pin Pressing

- Real-Time Force & Displacement Monitoring

- In-Process Quality Checks

- Automated Part Unloading

Performance Highlights

Exceptional Assembly Precision

The integration of servo and vision technologies guarantees that drilling and pin pressing are performed with sub-millimeter accuracy, leading to a significant reduction in defects and rework.High Throughput & Efficiency

The machine’s dual-action capability and fast cycle times allow for continuous, high-volume production, helping you meet demanding schedules without compromising on quality.Minimal Downtime

With robust components, self-diagnostic capabilities, and a user-friendly interface, the system is designed for maximum uptime and easy maintenance, minimizing service interruptions.

- Have Questions? Ready to Automate?