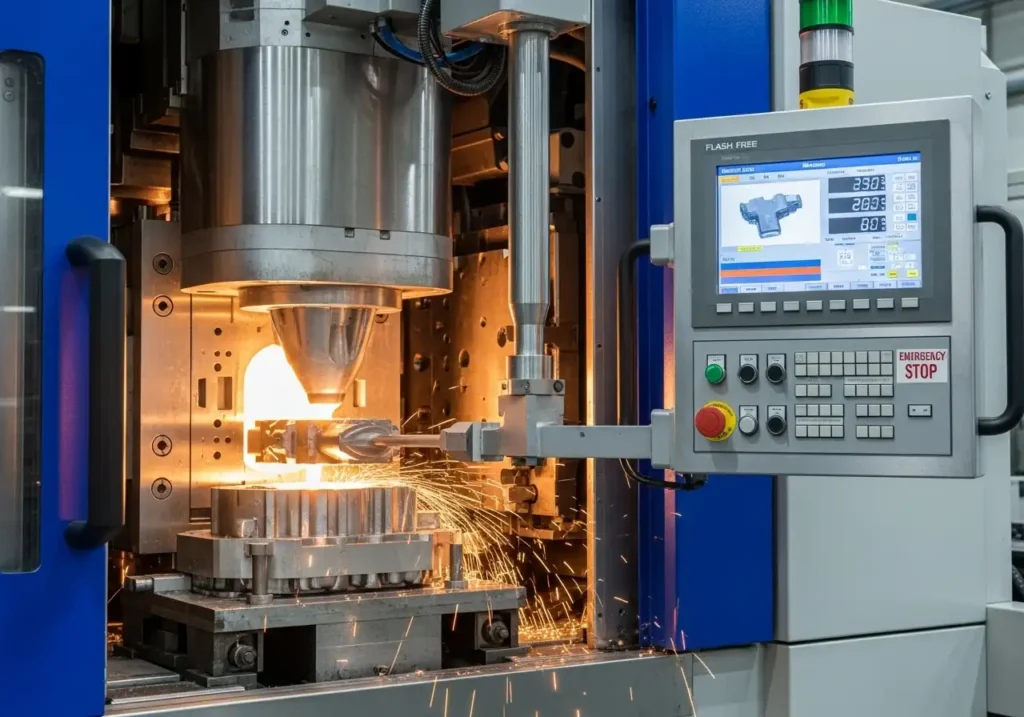

Flash-Free Die Casting Machine

Motionworks Robotics’ Flash-Free Die Casting Machine provides a fully automated, high-pressure solution for producing complex metal components with unparalleled precision and efficiency. Designed for Tier-1 automotive and industrial suppliers, this system eliminates the common problem of “flash” (excess metal) during the casting process, ensuring a perfect finish every time.

Utilizing advanced multi-slide hot-chamber technology, our machine injects molten metal directly into the parting line of the die blocks. This proprietary method, combined with real-time injection control, delivers net-shaped parts at high speeds, significantly reducing scrap and the need for secondary trimming operations. The result is a cleaner, more reliable, and cost-effective production process.

Key Features

Flash-Free Technology

Our innovative injection system eliminates the need for overflows and sprues, preventing the formation of flash and ensuring every part is produced to its final shape. This saves material and eliminates the need for post-processing.

High-Precision Robotics

Achieve repeatable and accurate part production with our advanced PLC and HMI-controlled system. The machine provides precise temperature and pressure control, ensuring consistent part quality and superior mechanical properties.

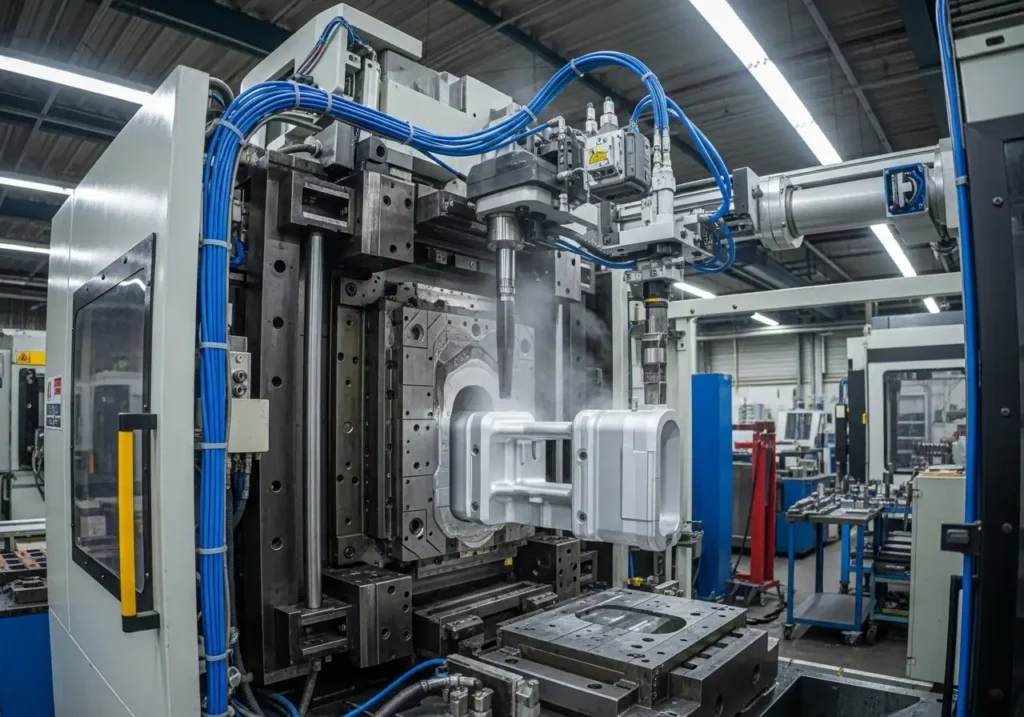

Multi-Slide Design

With up to six independently movable slides, our machine can produce intricate, small components with complex geometries that are not possible with conventional two-part molds. This offers greater design freedom and part consolidation.

Satisfaction Rate

What the Line Does

Our Flash-Free Die Casting Machine is engineered to handle

- Hot-Chamber Injection

- Multi-Slide Die System

- Real-Time Injection Control

- Automated Part Ejection

- Precision Temperature & Pressure Regulation

- Zinc & Other Low-Melting-Point Alloys

- No Sprue or Overflow Required

Performance Highlights

- Consistently High Throughput

The machine’s fast cycle speeds and automated operation allow for rapid, continuous production, helping you meet high-volume demands with ease. - Exceptional Casting Precision

The flash-free process and multi-slide design ensure every component is a net-shape part with consistent quality, reducing rework and improving overall reliability. - Minimal Downtime

Equipped with built-in diagnostics and an error messaging system, the machine is optimized for high uptime. The modular design and easy-to-access components make maintenance straightforward. - Reduced Material Waste

By eliminating flash and sprues, the machine significantly cuts down on material waste, leading to a more sustainable and cost-effective manufacturing process.

- Have Questions? Ready to Automate?