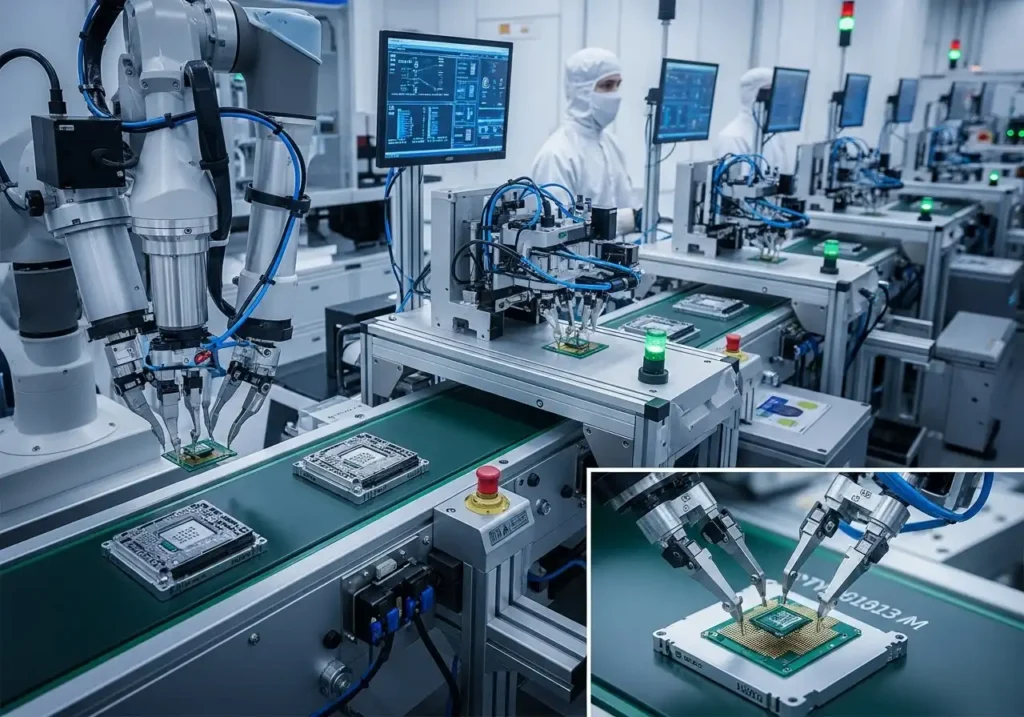

ECU Assembly Automation

High-Precision Assembly. Flawless Quality. Unmatched Reliability.

Motionworks Robotics’ ECU (Electronic Control Unit) Assembly Automation system delivers a high-precision, fully automated solution for the complex assembly of automotive and industrial ECUs. This system is designed for Tier-1 automotive electronics manufacturers who require impeccable quality, traceability, and high throughput in their production processes.

Engineered with advanced robotics, precision dispensing systems, and sophisticated vision technology, our system ensures every component is placed, soldered, and tested with sub-micron accuracy. It integrates seamlessly into your production line, using intelligent vision systems for real-time quality inspection and traceability. The result is a highly reliable and efficient machine that significantly reduces manual labor, improves product quality, and increases overall production speed.

Key Features

Full Traceability & Data Logging

The system is equipped with an integrated data logging feature that records every assembly step, including component serial numbers, process parameters, and quality inspection results. This provides full traceability for every ECU produced.

High-Precision Robotics & Dispensing

Our SPM uses a high-speed, multi-axis robotic platform for precise pick-and-place operations. It is equipped with advanced dispensing systems for thermal paste and conformal coating, ensuring flawless application every time.

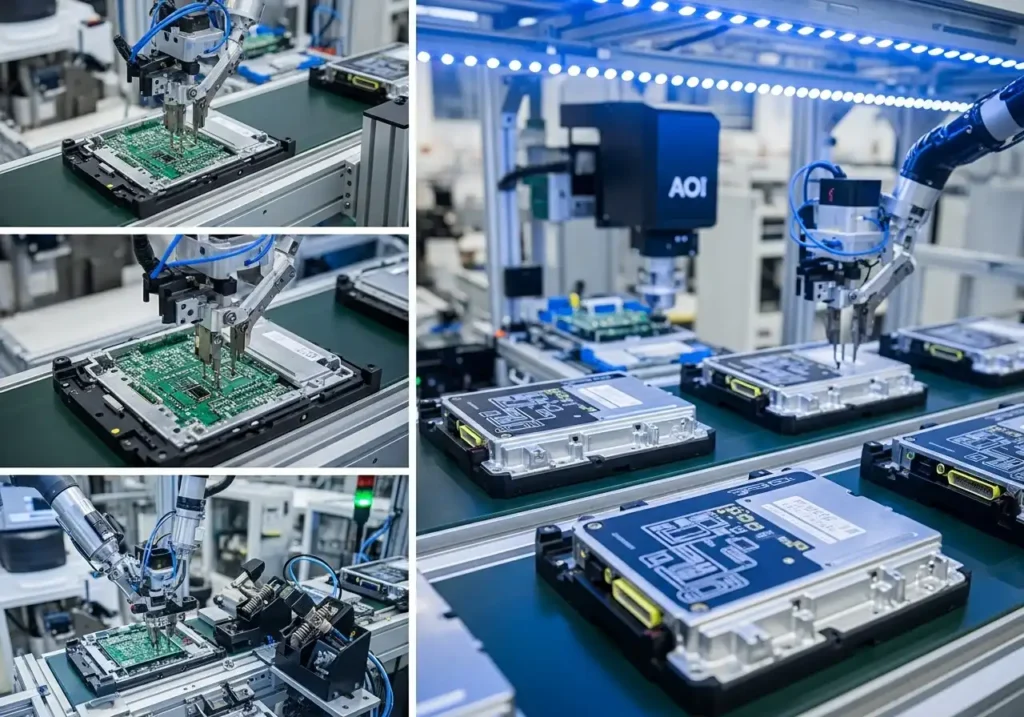

Integrated Vision & Quality Control

AI-powered cameras and sensors perform real-time quality inspection, verifying component presence, orientation, and solder joint integrity. This proactive quality control ensures every ECU meets the highest standards for performance and reliability.

Satisfaction Rate

What the System Does

Our ECU Assembly Automation is engineered to handle:

- Automated PCB & Component Handling

- High-Speed Pick & Place of Electronic Components

- Precision Dispensing of Thermal Paste & Coating

- Automated Screw Fastening & Connector Insertion

- Vision-Based Solder Joint Inspection

- In-Circuit & Functional Testing

- Full Traceability & Data Logging

Performance Highlights

Exceptional Assembly Precision The combination of robotics, precision dispensing, and vision technology ensures every component is installed with sub-micron accuracy, leading to a significant reduction in defects and rework.

High Throughput & Efficiency Designed for continuous, high-speed operation, the system maintains a smooth and consistent workflow, helping you meet demanding production targets without bottlenecks.

Unmatched Reliability With robust components, self-diagnostic capabilities, and a user-friendly interface, the system is optimized for maximum uptime and easy maintenance, minimizing service interruptions.

- Have Questions? Ready to Automate?