Battery Laser Welding Automation

Precise Welds. Strong Bonds. Maximum Safety.

Motionworks Robotics’ Battery Laser Welding Automation solution delivers a high-precision, fully automated system for welding battery cells, modules, and packs. This system is designed for manufacturers in the electric vehicle, energy storage, and consumer electronics industries who require flawless, hermetically sealed welds and maximum safety.

Engineered with advanced fiber laser technology and a multi-axis robotic platform, our system ensures every weld is performed with pinpoint accuracy and consistent penetration. It integrates seamlessly into your production line, using intelligent vision systems for real-time quality inspection and thermal monitoring. The result is a highly reliable and efficient machine that improves battery performance and safety while significantly reducing production time and costs.

Key Features

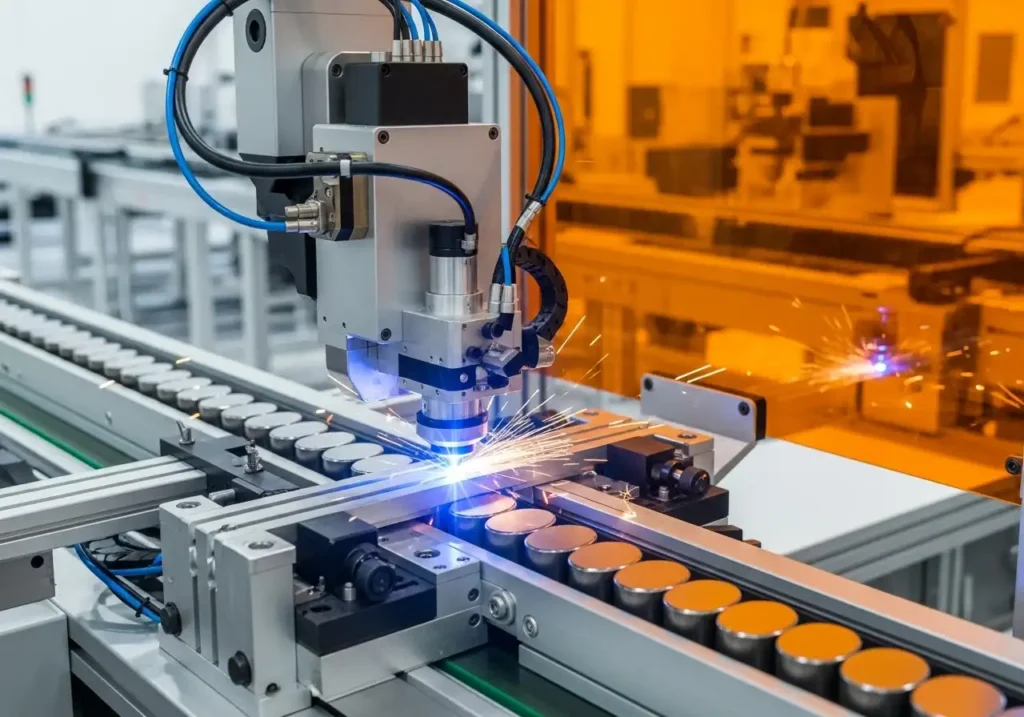

High-Precision Laser Welding

Our system utilizes a high-powered fiber laser to create precise, clean welds with minimal heat-affected zones. The non-contact process ensures a strong, hermetic seal for every joint, which is critical for battery integrity and safety.

Integrated Vision & Quality Control

AI-powered cameras and sensors perform real-time weld inspection, verifying seam quality, penetration depth, and thermal stability. This proactive quality control ensures every battery pack meets the highest safety and performance standards.

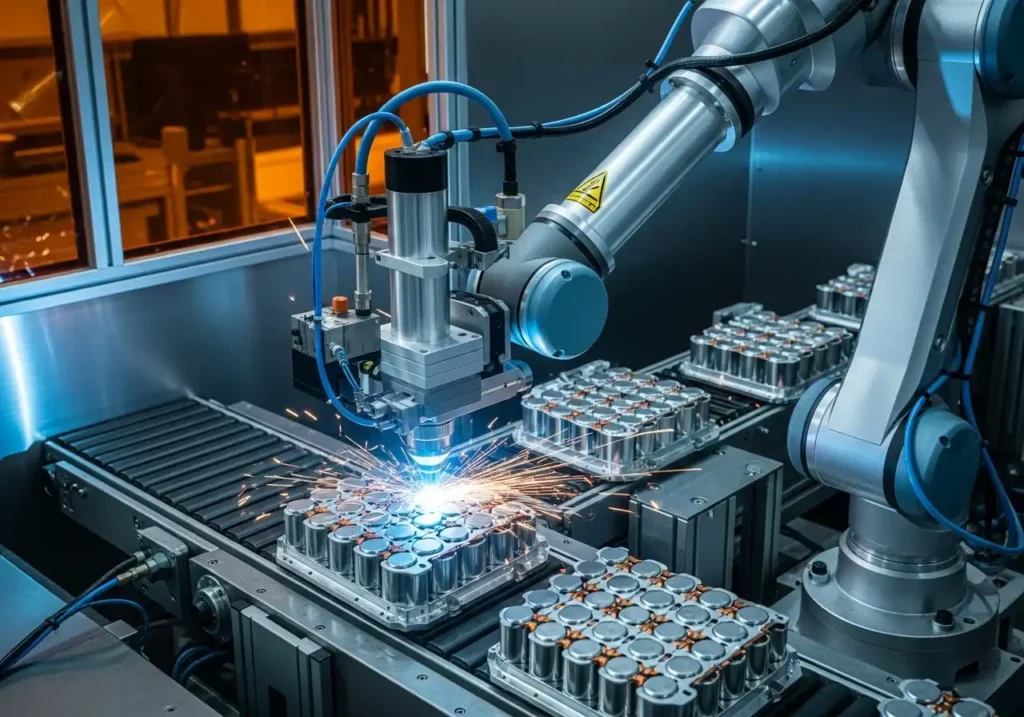

Robotic Handling & Safety

Our multi-axis robotic platform provides flexible, accurate handling of battery components. The system is enclosed in a certified laser safety cabinet with integrated fume extraction, ensuring a safe working environment for all operators.

Satisfaction Rate

What the System Does

Our Battery Laser Welding Automation is engineered to handle:

- Automated Part Loading & Positioning

- Vision-Based Weld Path Identification

- High-Speed Laser Welding of Cells & Busbars

- Real-Time Weld Quality Monitoring

- Hermetic Sealing of Battery Packs

- Automated Part Unloading

Performance Highlights

Exceptional Weld Precision The combination of advanced laser technology and robotic control ensures every weld is performed with sub-millimeter accuracy, leading to superior electrical connections and long-term battery reliability.

High Throughput & Efficiency Designed for continuous, high-speed operation, the system maintains a smooth and consistent workflow, helping you meet demanding production targets without bottlenecks.

Maximum Safety & Reliability With built-in safety features, self-diagnostic capabilities, and a robust design, the system is optimized for maximum uptime and operator protection, minimizing service interruptions.

- Have Questions? Ready to Automate?